20130429

I began to make the neck.

When I was sawing the blank for the scarf I accidentally cut my finger.

I was holding the head part for the past part of the sawing and the saw dropped on my index finger.

At first it didn't look too bad but I was bleeding quite a lot until I felt a bit faint.

Apparently the blood didn't clot until I reached home...

I check the saw blade there some part of my skin was there.

Preparing to saw the neck

Sawing the neck

Cut

Well the sawing isn't that good need to clean up with my plane.

Cleaning up the scarf joint

Close up of the red mountain cedar. Looks like Spanish Cedar

20130510

Continued on the neck, saw the pieces for the heel stack and ripped the center piece into 1/2.

Then I glued a center ebony spine to the main neck.

The 2 neck pieces were flipped over; left become right and right become left for better stability.

Shoot level the 2 sides of the neck

Shoot level the ebony piece

Saw the neck into 1/2s

Glue them up.

Glue and clamp

The main neck is done. Need to plane the ebony piece level with the neck.

20130802

It's been a long time since I worked on this guitar.

The top has been lying there in the solera for quite sometime.

Well the wait was due to several factoring including me concentrating on finishing up #3

I started to glue the neck together after confirming that the headplate size fits.

After that I can proceed to carve neck and heel; meanwhile the neck and heel block are glued separately for now.

Gluing the neck

Gluing the heel

20130807

I glued the headplate on and once it's dried it will be ready for carving the headstock shape.

Ready for gluing

Applying hide glue

Checking alignment

Clamped

20130815

I continued on the neck.

First I planed the sides of the head until it fits the headplate.

Next I saw and file to shape the head shape

The tuner holes were next and following by the slot holes.

All were perfect until the slot holes...

Because the location of the holes were next the tuner holes the Forstner bit got suck into the tuner holes..

And the hole went off the intended place 1/2 way in depth...

Luckily it wasn't too bad and can be remedied with some sanding.

Finally I file the tuner holes section; the string ramp part

My usual neck has a straight string ramp but this one has a rounded one due to the headstock carving which wasn't doen by me.

Chiselling away at the head-neck joint part to allow space for planing

Planing the side of the headstock to fit the headplate.

Saw off the excess in the headstock.

Sawn off the excess

Chisel to shape and smoothen with file later.

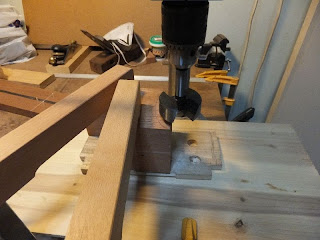

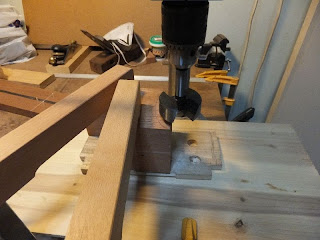

Drilling the tuner hole

Drilling the slot hole

The right bottom part where the forstner bit got off tracked into the tuner hole..

Saw away the excess slot

Chop off the excess

Saw away the nut part of the headplate

Clean up with chisel

Guide holes for heel block and neck; to help align the 2 during gluing

Head stock done (quite ok except for the mistakes)

Big 2" forstner bit for the heel arc curve part. But it drifted during the drilling I had to use a smaller bit to remove the waste and finish by rasp

The neck ready for gluing

Glue the heel to the neck and clamped.

20130819

I began to cut the side slots and rough shape the heel.

With a 5 degree wooden block guide, I started the cut with my douzuki.

After the slotting gets deep enough the guide block is removed and continue the sawing with the douzuki.

The hard hard is the 2nd cut of the same slot/side, the guide block is clamped to the new position.

After removing the guide block the saw will tend to drift.

I had to remove some of the waste (2mm thick) by chisel and widen the kerf using my western gent saw with a scraper spacer.

After both slots are done I saw the heel front front and shape with my rebate plate.

The front curve is shape with my roller sander drill attachment.

Guide block for the slot cut, it's angle at 5 degrees offset.

Checking the slot width after sawing. The square's thickness is about 2mm

Both slot done

Sawing away the heel's waste

Rough shaped heel.

20131007

Well it has been a while since the last update.

I was caught up with something so basically didn't have time to make any progress.

So now I am basically preparing the parts for assembly and this is the final part for the neck shaping the inner heel block.

I was pondering to update it here or under pre-assembly post but decide to update here for completion sake.

So I basically saw away the excess to taper the heel block and not make it so squarish.

Squarish will work as well just matter of looks and preference.

After that I spend quite sometime shaping it making it leaner and reducing the weight.

Sawing the excess in the inner heel block so that the foot is narrower and heel (top side) is broader.

Chisel the excess away after I round off the corners with file and rasp

Next I removed the end grain with my new LN scrub plane (it's narrow enough) Other planes are too wide...

The heel block rough shaped. Need to sand it more.