Welcome to my guitar building blog.

This blog describes my journey into the world of guitar building.

I like to share my experience of building and hopefully it can be of some help to all the guitar making enthusiast.

Hope you enjoy my blog post!

Showing posts with label Jigs. Show all posts

Showing posts with label Jigs. Show all posts

2020-10-31

Making the jigs for binding cutting

20200911

All along I am using the default trimmer router base for routing the binding channel.

It works well to certain extend, the only problem is that the binding channel reference is always to the top or back of guitar.

For the back where the curvature or doming is quite pronounced, the binding channel will be skewed.

So this time round I decide to make a jig that allows the binding channel to be routed with reference to the sides instead.

Most binding jig out there is based on this principle of referencing the sides instead of the top.

So I began to make the jig it actually quite a simple design, it acts like the router holder but with a longer guide so that it can reference the sides better.

Basically it acts like a marking gauge.

So I make the base and the guide rail separately and the way to secure them togehter is very similar to my circle cutter jig.

20201031

Next I need to make the holder for the guitar.

Normally, I just put it inside the solera with the side mould.

But in this case, because of the longer reference sides needed, the side mould cannot be used.

So I decide to modify one of my previous solera to be able to clamp down the body while exposing most of the sides for the binding cutting.

However, the solera has some warping so I added some wood members to correct the geometry accordingly.

Also I added a special way of clamping the body down.

As there is no neck attached, the clamping has to be a bit special.

I also drilled the dowels for rope tying for the binding.

I created a structure too to allow me to work on 1/2 the side of the guitar independently.

But this will make it more restrictive during the binding stage.

2013-01-06

Making the radius stick (sanding block)

I made a radius stick sanding block for the back.

Nothing special here draw the arc, spokeshave it and ensure squareness.

Finally glue some ply wood to join the 2 sticks to have enough area for sandpaper.

Nothing special here draw the arc, spokeshave it and ensure squareness.

Finally glue some ply wood to join the 2 sticks to have enough area for sandpaper.

2012-12-27

Making the solera v3

With the 10 string guitar build, the current side mold wasn't wide enough for the 10-string neck.

So I am left with 2 choice: either to cut the side mold or build a new one

Needless to say I build a new one.

This solera is flat without the elevated feature and with a movable side blocks instead of a side mold.

The process of making is alot simpler than my previous one.

Previously I had cut 2 more extra solera base and I simply use them for this make.

I glue them together and glued 2 pieces of pine below to support the solera.

Then I dished out the doming (about 4-5mm) and smoothen them with sandpaper.

After sanding I gave the base a coat of varnish for protection.

Next I cut the side blocks from the pine that I had.

There is some difference between the side blocks and my 1st solera.

In my 1st solera the slots are in the solera base, and for this v3 the slots are in the side blocks.

I drilled 2 holes in the side block base and use chisel to chisel them out.

With sharpened chisels this is very easy.

I drilled the corresponding holes in the solera base.

Finally I just need to find the hardware to fasten the side blocks to the solera.

I should be getting some winged nuts and hex bolts for that purpose

. One important aspect I am thinking of is to use rare earth magnet for holding the sides to the side blocks.

This way I don't need extra clamps and it's clean and easy.

How it works out I have to do some experiments.

Cut a slot for the head stock. This is design for 650mm scale length. I haven't decide if I wanna cut a slot for 640mm scale length or not (will be placed inner a bit)

The solera almost done. Checking the fit for 10-string neck. Noticed the side blocks has a lining to improve the strength of the gluing. The direction of the lining is same a guitar lining.

So I am left with 2 choice: either to cut the side mold or build a new one

Needless to say I build a new one.

This solera is flat without the elevated feature and with a movable side blocks instead of a side mold.

The process of making is alot simpler than my previous one.

Previously I had cut 2 more extra solera base and I simply use them for this make.

I glue them together and glued 2 pieces of pine below to support the solera.

Then I dished out the doming (about 4-5mm) and smoothen them with sandpaper.

After sanding I gave the base a coat of varnish for protection.

Next I cut the side blocks from the pine that I had.

There is some difference between the side blocks and my 1st solera.

In my 1st solera the slots are in the solera base, and for this v3 the slots are in the side blocks.

I drilled 2 holes in the side block base and use chisel to chisel them out.

With sharpened chisels this is very easy.

I drilled the corresponding holes in the solera base.

Finally I just need to find the hardware to fasten the side blocks to the solera.

I should be getting some winged nuts and hex bolts for that purpose

. One important aspect I am thinking of is to use rare earth magnet for holding the sides to the side blocks.

This way I don't need extra clamps and it's clean and easy.

How it works out I have to do some experiments.

Cut a slot for the head stock. This is design for 650mm scale length. I haven't decide if I wanna cut a slot for 640mm scale length or not (will be placed inner a bit)

The solera almost done. Checking the fit for 10-string neck. Noticed the side blocks has a lining to improve the strength of the gluing. The direction of the lining is same a guitar lining.

2011-09-27

Making the go-bar deck

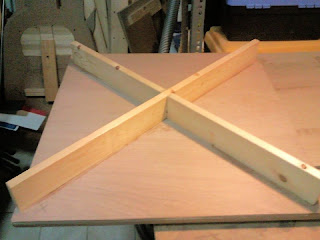

In order to glue the struts, I need to make the go-bar deck.

I was thinking to attach the top deck to the solera, which I will be making using 2 pieces of 1cm thick plywood.

This probably won't be strong enough and so I added a cross-bracing to the top.

I started making the notches in the bracing and it's a good way to improved my chiseling skill.

Now I am pretty confident of making a normal dado or mortise-tenon by chisel.

Not perfect fit but acceptable.

I realised the crucial part is that the chisel must be real sharp.

The rest is just getting them to fit.

Gluing 2 pieces of plywood together

Sawing the edges straight. After that I followed up by chiseling and planing to make the 2 pieces flushed.

Chiseling the notch

Cleaning the notch to make them fit.

Notch done

Gluing the x-brace down.

The middle part I use another scrap to press down.

I don't have any clamp that is that long reach.

X-brace done. The X-brace will help to keep the plywood flat too.

After that I drilled the holes for the top and bottom board.

I've decided not to attached the top board to the solera.

This makes it easier for me to use the deck for back struts too.

Due to the position of the X-brace I could not drill exactly at the corners but I have to drilled to fit the 2 boards.

I assembled the board with 3 legs, for the last leg the hole had some chipped pieces

I glued them back.

With just 3 legs, the assembly is kind of wobbly...

I wonder would it be able to withstand the pressure of the go-bars?

The last time I use the Aluminium go-bars on the table the entire table rose up...

I had put books and other heavy weight to weigh it down.

Well if the threaded rod doesn't work then I have to build using wood legs.

Drilling the hole 10mm to allow the threaded rods to go thru'

Assembly.

The parts

Go-bar deck assembled

Another view

Another view

Testing the deck. Test run of the gluing process and adjusting the height of the deck to exert enough pressure and the go-bars are not too curved.

Close up of the doming of the struts

I have made some more go-bars for the gluing.

4 for each struts 7x4 = 28 and 2 extra.

That should be enough to start the gluing process.

I was thinking to attach the top deck to the solera, which I will be making using 2 pieces of 1cm thick plywood.

This probably won't be strong enough and so I added a cross-bracing to the top.

I started making the notches in the bracing and it's a good way to improved my chiseling skill.

Now I am pretty confident of making a normal dado or mortise-tenon by chisel.

Not perfect fit but acceptable.

I realised the crucial part is that the chisel must be real sharp.

The rest is just getting them to fit.

Gluing 2 pieces of plywood together

Sawing the edges straight. After that I followed up by chiseling and planing to make the 2 pieces flushed.

Chiseling the notch

Cleaning the notch to make them fit.

Notch done

Gluing the x-brace down.

The middle part I use another scrap to press down.

I don't have any clamp that is that long reach.

X-brace done. The X-brace will help to keep the plywood flat too.

After that I drilled the holes for the top and bottom board.

I've decided not to attached the top board to the solera.

This makes it easier for me to use the deck for back struts too.

Due to the position of the X-brace I could not drill exactly at the corners but I have to drilled to fit the 2 boards.

I assembled the board with 3 legs, for the last leg the hole had some chipped pieces

I glued them back.

With just 3 legs, the assembly is kind of wobbly...

I wonder would it be able to withstand the pressure of the go-bars?

The last time I use the Aluminium go-bars on the table the entire table rose up...

I had put books and other heavy weight to weigh it down.

Well if the threaded rod doesn't work then I have to build using wood legs.

Drilling the hole 10mm to allow the threaded rods to go thru'

Assembly.

The parts

Go-bar deck assembled

Another view

Another view

Testing the deck. Test run of the gluing process and adjusting the height of the deck to exert enough pressure and the go-bars are not too curved.

Close up of the doming of the struts

I have made some more go-bars for the gluing.

4 for each struts 7x4 = 28 and 2 extra.

That should be enough to start the gluing process.

Subscribe to:

Posts (Atom)