Well I posted on the OLF and had different opinion on whether to inlay the back strip or not.

For a thing, I like both looks.

The back without the back strip looks nice and the look with the back strip fits the big rosette.

So I go ahead and do the back strip

The back strip consist of 3 alternating tiles same as the rosette: IRW, Bloodwood and Basswood.

I was choosing the router bit for the routing.

And decide on the widest one which is about 12.5mm

Minus the 2.x mm for the thickness of the purfling red / white, it's about 10mm wide tiles.

I use my purfling cutter to cut the correct width saw to size using my miter box.

I cut the red and white fiber using the purfling cutter too with a 1m rule as a guide.

To assemble I use my 2 Aluminium bar to glue the purlfing 1st.

Then I glue the tiles to the 1st purfling and sandwich the other side with the purfling.

I use white PVA as it dries clear and has longer open time.

Anyway I was lazy to heat up the hide glue.

After it dried, I check the looks with the back, with or without.

Checking the looks of the back strip

Assemble the tiles check for the correct width on all tiles and adjust with a plane

Cutting the fiber purfling

Glue the white fiber to the red.

Glued

Clamped.

With back strip

Without back strip which looks better?

When I decide to go ahead, I began the routing setup.

I supported the center back joint part and the sides of back.

They are of different height due to the curavture of the back struts.

But with different scrap they are well supported.

I clamp 2 Aluminium bar to the back to act as a guide.

After adjusting the guide until the router base is at the center of the back along the entire length, I clamp the guide tight and check the alignment again.

Previously I had routed a channel to test fit the router bit and tiles

Then I set the depth using that previously routed channel it's about 1.5mm deep.

The back is about 2.5 so I got some meat left in the back.

After all is set I route it and all goes well.

I glue in the back strip and left it to set.

The 2 Al bar router guide.

Well you guess it correctly it's the same bar I use for clamping the back strip.

Adjusting the bar to make sure it's correctly align using eyeball only :)

Set the depth using the previously routed test channel.

Close up of the depth setting; its about 1.5mm deep channel.

Ready to route

Channels routed; everything went well.

Apply glue in the channel

Glue the back strip into the channel

Clamp tight

After removing the clamp, well... the inlay wasn't perfect.

There are some gaps but I think I can fill it up with IRW dust.

After that I simple plane down the back strip to level but in the process I cause some tearout in the back

Hopefully I can sand it level.

After removing the clamp.

Planing it flush with the back surface

The shavings

Side view can see that it's pretty leveled

Tearout

Gaps...

Welcome to my guitar building blog.

This blog describes my journey into the world of guitar building.

I like to share my experience of building and hopefully it can be of some help to all the guitar making enthusiast.

Hope you enjoy my blog post!

Showing posts with label Backstrip. Show all posts

Showing posts with label Backstrip. Show all posts

2011-12-09

2011-02-23

Making the Meander Tiles

Some updates: My workshop apartment is undergoing some major upgrade, (changing of all the sewage pipes, water pipes etc...

So unfortunately, I won't be able to work on my guitar for a few months :(

Hope to work my guitar soon.

So unfortunately, I won't be able to work on my guitar for a few months :(

Hope to work my guitar soon.

I wanted to have a thick back strip for the guitar, and also possibly decorate the head-plate too.

So I thought of making a meander tile for it.

I originally thinking of a more complicated 2 fold meander pattern but settled for just one fold.

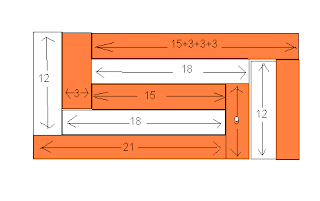

I started with the paper and calculated the width of each of the piece on the paper.

The centre strip was 15mm wide, and each piece thickness was 3mm.

So I add according and came out with a list of the width to cut.

I use Basswood for the white part and Indian Rosewood (double length head-plate) for the dark part.

To cut the strips from the head-plate I use my purfling cutter tool and it works like a charm.

I measure the width from the caliper (with some allowance) and set the tool width according.

Then when I cut the strips I just need to make sure the IRW / basswood edge is straight (by shooting on the shooting board) and then exert a constant pressure on the edge while i glide the purfling cutter on the head-plate.

I score on one side first and then flip on the reverse side and continue until it cuts completely.

Then I shoot both pieces to get a straight edge.

The main piece has to be shot to be straightened too, for the next cut.

Here are the pics:

Planning for the Meander pattern.

Nearly did a width calculation mistake for one of the piece (less 3mm)

A clearer picture of the design.

All dimensions in mm.

All dimensions in mm.

Measure the width setting on my purfling cutter.

Shooting to straighten the edge.

Cut the strips from the head-plate.

Dry assembly looks good.

The gluing part needs lots of clamp and clips.

Luckily I have lots of clamps around.

I use normal PVA white glue for the job because of the open time.

Anyway it dries clear and it's not structurally crucial, so PVA glue will suffice.

Gluing the 1st strip

Simple just use the clips

After some pieces. The meander is taking shape

More clamps are employed as the meander tiles gets thicker

S-shape formed

More clamping

Amost done.

Tada... Completed

Next to come is to cut up the tiles.

So in order to cut properly I made a miter box to be used with my douzuki saw.

Miter box for cutting up the tiles

Another view

Using the miter box.

The right block is thicker than the left.

It's meant as a stop to control the thickness of the tile slice.

The right block is thicker than the left.

It's meant as a stop to control the thickness of the tile slice.

Sawing the tile

The full view of the set-up.

The 1st tile sawn. So far so far

The pattern forming up.

My meander back strip (dry assembly).

The 2 white lines are for the look and feel.

The actual one will be thinner.

The 2 white lines are for the look and feel.

The actual one will be thinner.

After a number of tiles sawn.

You can see the dust piling up.

You can see the dust piling up.

My collection of tiles ready for installation.

Should be able to inlay on 2 or 3 backs.

Should be able to inlay on 2 or 3 backs.

Subscribe to:

Posts (Atom)